SHARE

The Graphitization Phenomenon

- By: Chris MacDonald, President and CEO

The information contained herein is intended to educate asset owners on the importance of the right type of inspection to determine condition, and details related to graphitization. The inspection suited to obtaining reliable data is essential to managing critical assets that are the profit center of every utility in the water and sewer industry.

Introduction

In the complex world of water and sewer pipeline management, one of the less visible yet significant challenges is the phenomenon of graphitization, particularly in ductile iron pipelines. This process, often undetectable through conventional inspection methods, poses a serious risk to the structural integrity and longevity of these critical infrastructures. This article delves into the intricacies of graphitization in ductile iron pipelines, exploring its causes, progression, and the challenges it presents in detection and management.

The criticality of this article was derived from hearing countless stories about pipelines being exposed and a trusted advisor of the pipeline owner saying “the pipe looks to be in good condition”. This has been repeated probably millions of times to countless asset owners over the past 50 years. CPM Pipelines has been involved in many projects over the past 10 years investigating corrosion using various inspection techniques over the past decade.

What we know with certainty is that you can not simply look at a pipe and determine its condition. Defects and deficiencies like graphitization are not visible to the naked eye or a CCTV inspection. Electromagnetic or ultrasound inspection technologies must be utilized to identify this type of pipe wall deficiency.

Understanding Graphitization in Ductile Iron Pipelines

Graphitization is a form of material degradation that affects ductile iron, a common material used in water and sewer pipelines. This process involves the gradual transformation of the iron carbides in the ductile iron into graphite. The graphite formation leads to a change in the microstructure of the material, resulting in a decrease in strength and an increase in brittleness. Again, these types of anomalies are not visible or easily identifiable.

Causes and Contributing Factors

The primary cause of graphitization in ductile iron pipelines is long-term exposure to certain environmental conditions. Key factors include:

Chemical Environment: The composition of the water or sewage, particularly the pH and presence of certain chemicals, which can accelerate the graphitization process.

Oxidative Conditions: Exposure to oxygen, especially under fluctuating pressure and flow conditions, can contribute to the oxidation of iron carbides.

Temperature Fluctuations: Although less significant than in high-temperature applications like steam pipelines, temperature variations can still influence the rate of graphitization in water and sewer systems.

Microbial Activity: Certain bacteria can influence corrosion and indirectly contribute to conditions favorable for graphitization.

Age of the Pipeline: Older pipelines are more susceptible due to prolonged exposure to these conditions.

The Challenge of Detection

One of the primary challenges with graphitization in ductile iron pipelines is its detection. Unlike external corrosion or physical damage, graphitization does not significantly alter the external appearance of the pipe. Traditional visual inspections, therefore, are largely ineffective in identifying this issue. The internal changes are microscopic and gradual, making early detection particularly challenging without resorting to advanced techniques like ultrasound or magnetic analysis.

The Non-Invasive Assessment Techniques

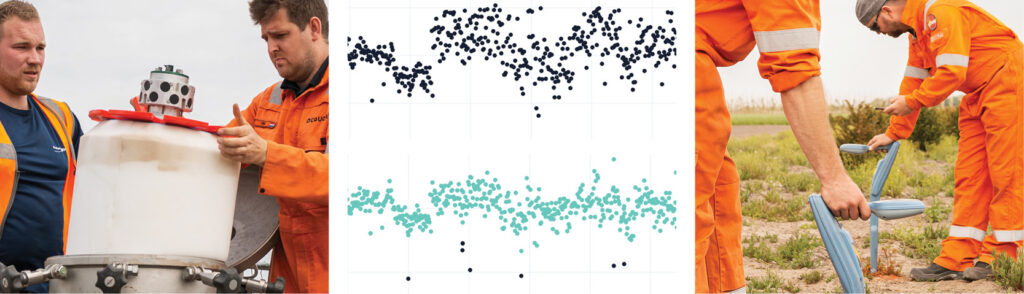

While advanced technologies like Acquaint’s Acquarius, an ultrasonic, multi-sensor in-line inspection tool or magnetic testing offer the most reliable results, there are other methods to infer the presence of graphitization:

Water Quality Analysis: Regular monitoring of water quality can provide indirect indicators of pipe degradation. Changes in certain parameters might suggest material breakdown.

Pressure and Flow Monitoring: Unexplained changes in pressure or flow rates can be symptomatic of internal degradation, including graphitization.

Historical Data Analysis: Examining the age, installation conditions, and maintenance history of the pipeline can help assess the likelihood of graphitization. These are critical first steps that can be taken to help in deciding to move toward a more comprehensive in-line inspection.

Visual Inspection of Accessible Parts: While limited, inspecting exposed sections of the pipeline for signs of corrosion or degradation can offer clues. These clues can be used to perform ultrasound testing on locations where access to the pipeline is available.

Conclusion

Graphitization in water and sewer ductile iron pipelines represents a significant and often hidden challenge. Its insidious nature makes early detection difficult, posing risks to the integrity and functionality of these essential systems. Understanding the causes and progression of graphitization is crucial for developing effective management and maintenance strategies. While advanced diagnostic tools like Acquaint’s Acquarius offer the best detection capabilities, a combination of indirect assessment methods and a proactive approach to asset management can also play a vital role in mitigating the risks associated with this complex phenomenon. As our infrastructure ages, prioritizing research and development in this area becomes increasingly important to ensure the reliability and safety of our water and sewer systems.