SHARE

Considerations for Designing the Outer Diameter of FFRP Liners in Pipe Rehabilitation

- By: Aaron Homing Ni, Asoe Hose Manufacturing Inc.

Introduction

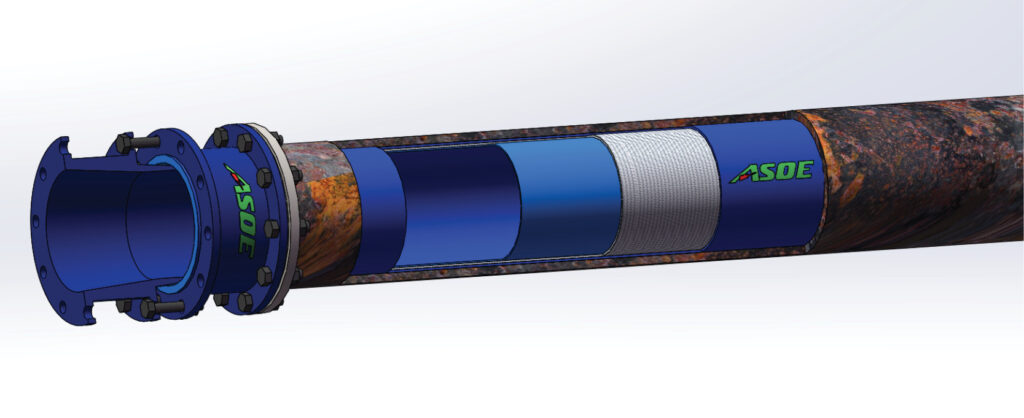

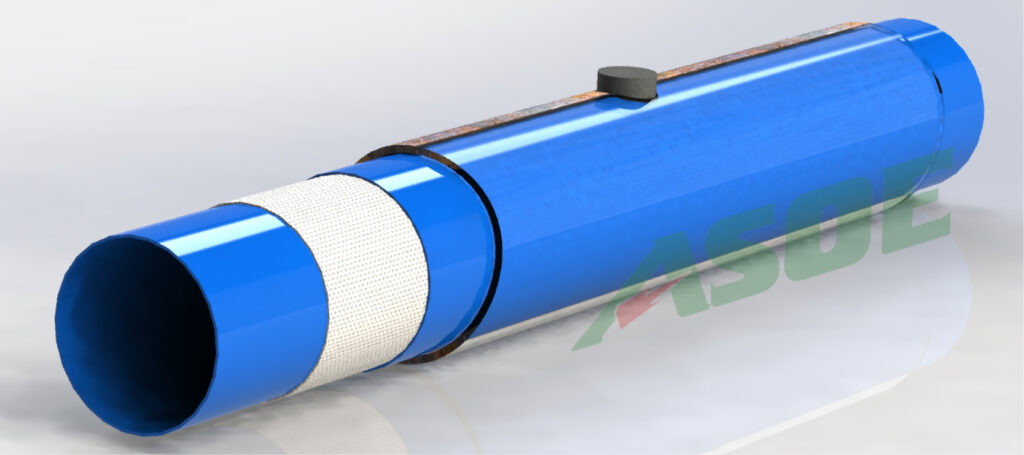

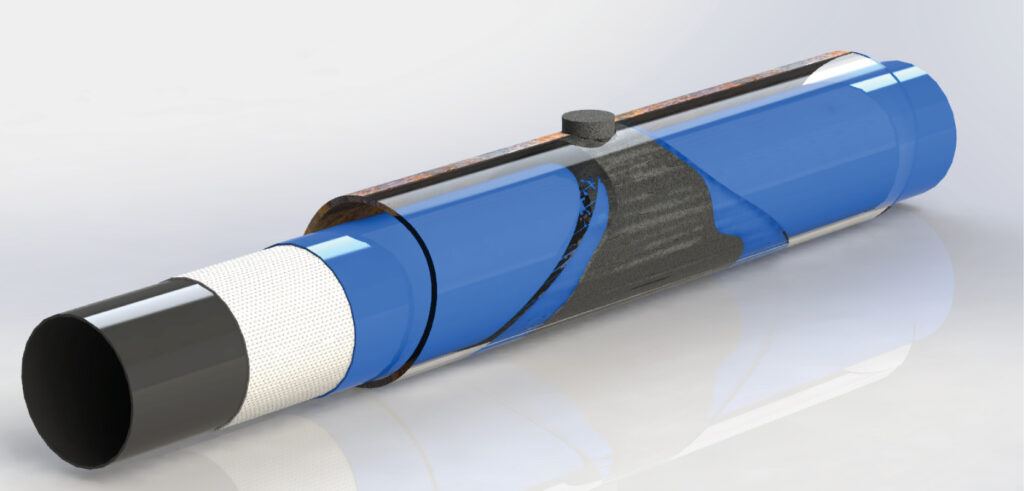

In the field of pipe rehabilitation, Flexible Fabric Reinforced Pipe (FFRP) liners have emerged as a popular solution for restoring the integrity and hydraulic performance of deteriorating pipelines that are structurally intact. Determining the appropriate outer diameter (OD) of the FFRP liner is a critical consideration that requires careful attention. This article delves into the importance of selecting the appropriate outer diameter for FFRP liners and the implications it has on pressure pipe rehabilitation projects.

FFRP Standardization Challenges

Several standards, including ISO11298-1 and ISO11298-11, have been established with the objective of standardizing the utilization of fold and form replacement pipe with inserted liner techniques. However, these standards exhibit a significant gap when it comes to providing explicit guidance to pipeline owners on designing the OD of FFRP liners. This lack of clarity presents challenges for the industry as it strives to undertake pipe rehabilitation projects with the highest level of precision and accuracy.

To address the lack of OD design guidelines, companies like Asoe Hose Manufacturing Inc. have stepped up to offer customized solutions. Asoe demonstrates the ability to design and manufacture FFRP liners with customized ODs to meet the diverse needs of different pipe types and sizes to be rehabilitated to enhance flexibility in their selection. For instance, when rehabilitating a 20-inch water pipeline, Asoe offers a variety of OD options, such as 17.875-inches, 18.5039-inches, 18.7008-inches, 18.8976-inches, 19.0945-inches, and 20.2913-inches.

The Importance of Close Fit FFRP

The primary objective when selecting an FFRP liner OD is to ensure a close fit between the liner and the host pipe under operating pressure. Achieving a snug fit is crucial as it eliminates the presence of an annular space or gap between the liner and host pipe, preventing long term effect to the liner. For example:

- The accumulation of corrosion within the pipe, root growth and subsequent leaks can result in soil infiltration, potentially leading to a reduction in the cross-section of the pipe and compromising its longevity.

- Deformations of the host pipe diameter.

- Crack formation.

- Groundwater containing impurities, contaminants and microorganisms. These impurities can include chemicals, heavy metals, bacteria, viruses and other pathogens. When groundwater infiltrates pipes, it can introduce these impurities into the system.

If smaller OD liners, such as 17.7165-inches, 17.874-inches, or 18.1102-inches, are installed, an annular space is created. This gap becomes an entry point for water, soil, and sand to infiltrate the host pipe through leaks, and can damage the rehabilitation liner. In cases where the water supply is temporarily terminated, vacuum pressure can develop within the pipeline. If the vacuum pressure reaches a significant level, the FFRP liner may collapse temporarily, leading to further sand and earth ingress. Subsequent resumption of water supply causes the water within the annular space to be squeezed out, but the sand and earth remain, accumulating over time. Although the liner is expected to be subject to the groundwater pressure practically in all design cases, other loads may be transferred on the liner in some way during the service life of the liner if the host pipe deteriorates further, or the surrounding soil weakens.

These accumulations can gradually press against the liner, potentially choking its functionality and necessitating pipe rehabilitation once again. Furthermore, a close fit between the FFRP liner and the host pipe minimizes the reduction in the liner’s inner diameter, ensuring maximum flow and hydraulic efficiency.

Requirements for OD Selection

Based on these considerations, two key requirements emerge for selecting the OD of FFRP liners in pipe rehabilitation projects as follows:

REQUIREMENT ONE

Close Fit under Operating Pressure

Owners must choose FFRP liners that can closely fit the inner wall of the host pipe when subjected to operating pressure. If owners install FFRP liners with ODs of 17.7165-inches,18.874-inches, or 18.1102-inches in a 20-inch pipeline, it will result in the formation of an annulus space. This space provides an entry point for water, soil, and sand to infiltrate the host pipes through leaks, and fill the gap. In the event of temporary water supply termination, vacuum pressure may occur within the pipeline. When the vacuum pressure reaches a certain level, the FFRP liner could temporarily collapse, allowing more sand and soil to enter the annular space.

Upon resumption of water supply, the water within the annular space can be expelled, but the sand and earth will remain trapped. If water supply disruptions occur repeatedly, the accumulation of sand and earth will progressively increase, exerting infinite pressure on the liner. This accumulation can cause the FFRP liner to become choked, necessitating pipe rehabilitation. Additionally, when the FFRP liner closely fits the inner wall of the host pipes, it minimizes the reduction in the liner’s inner diameter (ID), ensuring maximum flow. This close fit is crucial for maintaining optimal hydraulic performance. The range of OD options provided by Asoe allows owners to make an informed decision that caters to the specific requirements of their pipe rehabilitation projects.

REQUIREMENT TWO

Avoiding OD or exceeding ID

It is essential to ensure that the OD of the FFRP liner does not exceed the ID of the host pipe. If the OD is larger than the ID, the liner will not be able to fully expand within the pipe, leading to a decrease in flow capacity. This limitation emphasizes the significance of meticulous OD selection to preserve the hydraulic performance of the rehabilitated pipeline.

REQUIREMENT THREE

Grouting or patch rehabilitation is necessary to close leaks and cracks if annular space between host pipe and liner exist

Without closed-fit, all leaks and cracks should be closed by grouting or other patch rehabilitation techniques to avoid soil infiltration. In many scenarios it is impossible to close leaks and cracks on the host pipes by grouting or patch techniques when they are below the ground water level, or submersed.

Close fit FFRP is preferred due to its superior structural integrity, leak prevention, improved flow capacity, reduced contamination risk and long-term performance benefits.

Conclusion

Determining the suitable OD for FFRP liners in pipe rehabilitation is a crucial factor that profoundly impacts the project’s success and longevity. Although existing standards may not provide clear directives on this matter, Asoe Hose Manufacturing, Inc. specializes in customized solutions that cater to owners’ precise needs. By placing emphasis on achieving a tight fit between the liner and the host pipe, it can effectively mitigate the risks associated with the formation of an annular space and ensure the optimal hydraulic performance of the rehabilitated pipeline.

Author: Aaron Homing Ni

Co Authors: Chew, Chow Cher, Ital-TT Pte Ltd, Singapore and Ni, Houming, Asoe Hose Manufacturing Inc. China

CPM Pipelines and Asoe Hose Manufacturing, Inc. extend acknowledgement to Professor Tom Iseley, PhD, P.E. Dist. M. ASCE, PWAM for his continuous support to Asoe’s research in trenchless rehabilitation of pressure pipes utilizing FFRP.

BulletLiner System® FFRP is a registered trademark in the U.S., and NSF 61 certified through The Public Health and Safety Organization.