LIFT STATION and MANHOLE REHABILITATION

FRP Panels

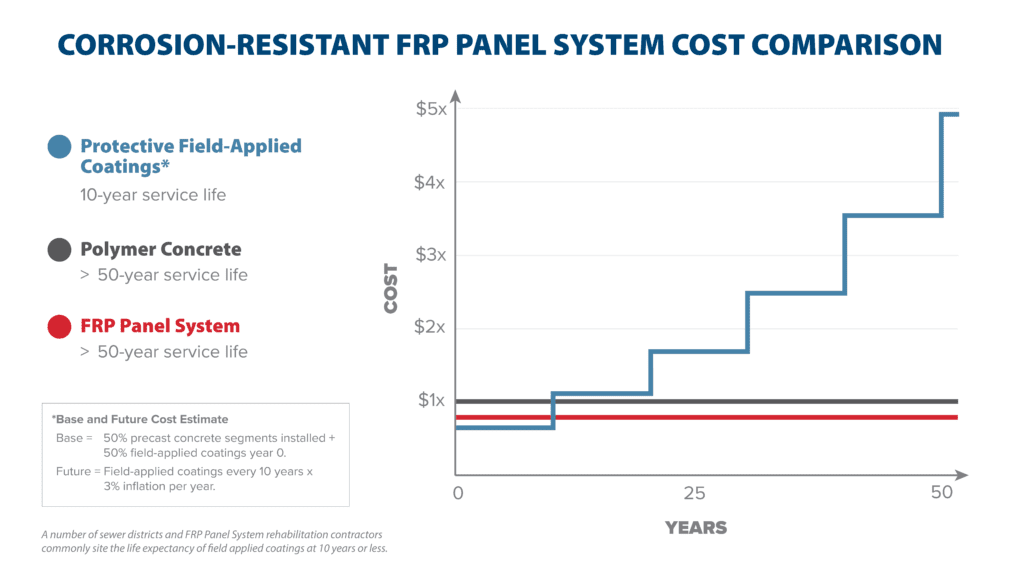

Quick to install, maintenance-free corrosion protection for wastewater structures.

Each half-inch thick composite panel consists of seven layers, including a high-strength honeycomb core and multiple layers of fiberglass and fleece. The outer surface is covered with FRP gel coat, the same material we use for our other lined products. The FRP gel coat is designed and tested to resist highly corrosive hydrogen sulfide gases commonly found in municipal wastewater systems. The panels are mechanically anchored to the inside of a structure and then sealed to form a gas- and water-tight lining.

FRP panels are customized to the unique specifications of each project. Using a 3D scanner, a representative digital model of the interior structure is created, which is used by our engineering team to design a panel layout to fit existing configurations and accommodate for features such as inlet pipes, access hatches, and flow channels.

- Economical and reliable solution

- Field inspected, qualified, and engineered system

- Third-party tested for corrosion resistance

- Customizable design

PVC Manholes

Perfect pipe consists of reinforced concrete pipe (RCP) with an integrated high density polyethylene (HDPE) liner that is wet-cast in the pipe wall forming a corrosion-proof barrier. The pipe is ideal in direct bury, trenchless, high loading, and high ground water applications. Perfect Lined Manhole System integrates a monolithic base and an FRP liner with HDPE protected riser sections and lid. The one-pour base eliminates cold joints and connects to nearly any plastic, clay, concrete, or fiberglass sewer pipe.

Proven mechanically resistant to raw sewer, Geneva Pipe and Precast’s Perfect Lined Manholes are revolutionizing municipal wastewater management. The corrosion resistant pipe and manhole system has an anchored liner that provides 100% coverage and creates a smooth laminar flow with a tight seal. Utilizing an innovative design, the joints require no field welds in most sizes and can connect to most new or existing systems. The Perfect Lined Manhole System has a design life of 100+ years in most sanitary sewer environments.