The Butterfly Valve Mystery

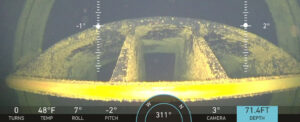

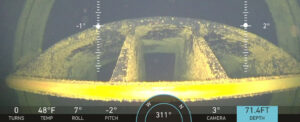

CPM’s recent project with a water utility client captured amazing footage providing a simple explanation for the (considered) inconsistent data captured through the client’s modeling software.

Protecting human divers one Deep Trekker PIVOT inspection at a time. How a subaqueous swimming CCTV inspection solved the unknown in a 48-inch, potable water, intake pipeline 600-feet below.

CPM was hired to provide a CCTV inspection utilizing the Deep Trekker PIVOT in a critical water reservoir that stores millions of gallons of water. The reservoir was located on the side of a mountain, with the actuator located at the bottom. Cause for the inspection was to determine if the butterfly valve was properly opening and closing based on the actuator readings, which appeared to be inaccurate.

CPM’s certified confined space entry technicians navigated the Deep Trekker PIVOT gracefully through the pipeline, operating the thrusters to move laterally, pivot effortlessly and withstand the strong current against the flow of water. In about 30 minutes the Deep Trekker PIVOT swam approximately 600-feet down the pipeline, in water 55-feet deep, to the location of the malfunctioning butterfly valve, where they maintained constant communication with the technicians manually operating the actuator. Deep Trekker PIVOT’s HD, 1080p camera system with lights captured crystal clear video and images utilizing 200º range of motion, allowing the contractor to determine that the butterfly valve had flipped 180º, causing improper sealing. This in turn caused the pressure side to receive an inaccurate actuator reading.

Unknown solved and repairs are in order. No video processing or downloads. No waiting. No need for divers with the accompanying risk, cost, and coordination.

CPM’s recent project with a water utility client captured amazing footage providing a simple explanation for the (considered) inconsistent data captured through the client’s modeling software.

CPM was contracted to perform a condition assessment inspection along two sections of 8-inch ductile iron pipe (DIP) waste activated sludge lines located in Arizona.

CPM was contracted to perform a phased pipe condition inspection utilizing INGU Pipers® free floating pre-screening inspection tools, Electromagnetic Bracelet Probe™ (BP) scanning, and ultrasonic thickness (UT) measurements on two wastewater force main pipelines.

An Arizona suburb pursues a long-term program to identify and locate leaks across its potable water pipeline system.

How one North Texas city is using new technology to protect its constituents from unforeseen water outages and loss.

Blazing the trail of large diameter pressure pipe rehabilitation in the U.S.