The Butterfly Valve Mystery

CPM’s recent project with a water utility client captured amazing footage providing a simple explanation for the (considered) inconsistent data captured through the client’s modeling software.

CPM Pipelines (CPM) was referred to a local city as a pipeline assessment technology expert. The city was pursuing a long-term program to identify and locate leaks across their potable water pipeline system. As a demonstration of technology and expertise, CPM performed an acoustic leak detection survey across several miles of water distribution pipeline in a residential neighborhood. CPM utilized a phased approach to canvas as much pipeline footage as possible, where after points of interest were investigated in detail to determine the existence and location of leaks.

CPM technicians met with the city’s staff to gain an understanding of their goals and expectations as well as to showcase the type of equipment suitable for such a program. After establishing an approach for carrying out a leak survey of the water system, the city agreed with CPM’s request to perform a demonstration of the equipment in a residential neighborhood. The system consisted of mostly 6- to 12-inch asbestos cement (AC) pipeline.

CPM was provided with a quarter section map illustrating the waterline system in the neighborhood and established the most advantageous locations at which to place acoustic leak detection sensors. The investigation began with the deployment of the Gutermann ZONESCAN 820 loggers to record data beginning at 2:00am the following day. The loggers were collected the following day, and the data uploaded. After a short processing period, a map was produced based on the acoustic information gathered overnight.

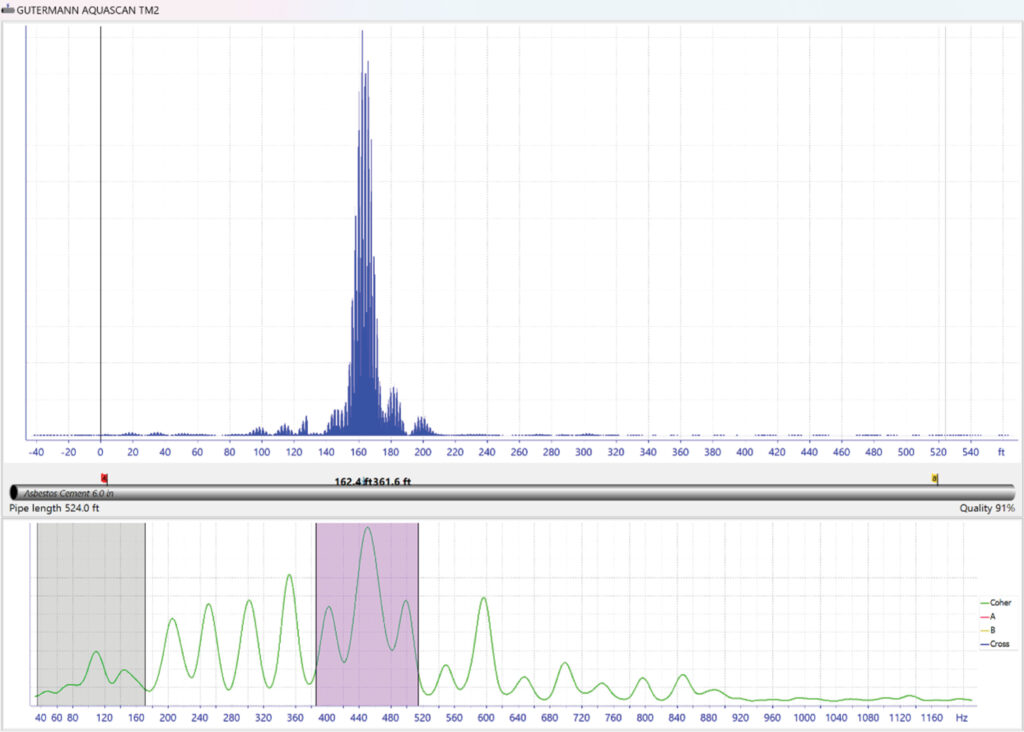

CPM technicians used the provided quarter section map to add the pipeline sections to connect the various segments between loggers on the map. Several areas illustrated a high confidence of leak presence based on the acoustic data.The loggers bracketing this section of pipe both returned very high leak scores. Additionally, three separate correlations occurred (points at which both loggers detected leak noise at the same location). This level of evidence is highly suggestive of a leak or leaks and warrants further investigation with the Gutermann AQUASCAN TM2 system. The logger score of 56 between the two higher scores suggests multiple leaks may be occurring in this area. Additionally, the loggers bracketing (confidential location) returned moderate scores warranting further investigation. Lastly, the loggers bracketing (confidential location) (scores of 77 and 57) did not correlate but the scores are high enough for additional surveying. The data collected by the loggers at each of the locations dictated further investigated with the TM2 system.

Based on the data collected by the 820 loggers, the TM2 system was deployed such that the sensors bracketed the segment of pipe where 820 correlations occurred or at locations where logger scores were moderate/high. Once in place, the system runs for 15-20 minutes to ensure that enough data is collected to make an accurate judgment of the presence of a leak or leaks. For additional quality control, several TM2 surveys are performed to ensure any potential leaks are repeatable. The software presents the approximate distance of the leak between the two TM2 sensors as well as the confidence rating. An output from the TM2 software for each survey performed was included in the final deliverables. The bracket distance includes any bends or alignment changes in the pipe, as opposed to a straight line between sensors. GPS coordinates included were approximate, and CPM field technicians marked the locations via spray paint during the investigation.

ZONESCAN 820 acoustic leak correlators were deployed overnight to collect leak noise data. The loggers detect the noise signature associated with a leak and provide a score for the likelihood leaks near the sensor. CPM used this data to perform a more refined investigation with the use of the TM2 leak detection system along pipeline segments suspected of having a leak. The TM2 software provides a confidence rating of 0-100%, and in most cases ratings over 90% can be assumed to have a very high probability of a leak. The system provides precise footages from each sensor bracketing the leak location such that the precise location of the leak can be marked.

Based on the two-day leak detection survey, a total of three leak locations were identified with a high level of confidence.

CPM’s recent project with a water utility client captured amazing footage providing a simple explanation for the (considered) inconsistent data captured through the client’s modeling software.

CPM was contracted to perform a condition assessment inspection along two sections of 8-inch ductile iron pipe (DIP) waste activated sludge lines located in Arizona.

CPM was contracted to perform a phased pipe condition inspection utilizing INGU Pipers® free floating pre-screening inspection tools, Electromagnetic Bracelet Probe™ (BP) scanning, and ultrasonic thickness (UT) measurements on two wastewater force main pipelines.

Protecting human divers one Deep Trekker PIVOT inspection at a time. How a subaqueous swimming CCTV inspection solved the unknown in a 48-inch, potable water, intake pipeline 600-feet below.

How one North Texas city is using new technology to protect its constituents from unforeseen water outages and loss.

Blazing the trail of large diameter pressure pipe rehabilitation in the U.S.